고정 헤더 영역

상세 컨텐츠

본문

There are a set of questions that seem to be commonly-used in interviews and classes when it comes to object-oriented design and analysis. This is one of them; unfortunately, my OOP professor in college never actually gave an answer to it, and so I've been wondering.The problem is as follows: design a basic set of objects/methods to be used to simulate an elevator bank. What are the objects and their attributes/methods?For the sake of argument, let us assume that our building has twenty floors; the bottom floor is the lobby, and the second floor connects to the parking garage (therefore, people will enter/exit the building on either the bottom floor or the second floor). There is one elevator bank that services all the floors; there are three elevator shafts in the elevator bank, and one elevator per shaft.What would be the correct way to model this in an object-oriented model? First there is an elevator class. It has a direction (up, down, stand, maintenance), a current floor and a list of floor requests sorted in the direction.

It receives request from this elevator.Then there is a bank. It contains the elevators and receives the requests from the floors.

These are scheduled to all active elevators (not in maintenance).The scheduling will be like:. if available pick a standing elevator for this floor. else pick an elevator moving to this floor. else pick a standing elevator on an other floor. else pick the elevator with the lowest load.Each elevator has a set of states. Maintenance: the elevator does not react to external signals (only to its own signals).

Stand: the elevator is fixed on a floor. If it receives a call. And the elevator is on that floor, the doors open. If it is on another floor, it moves in that direction. Up: the elevator moves up.

Each time it reaches a floor, it checks if it needs to stop. If so it stops and opens the doors. It waits for a certain amount of time and closes the door (unless someting is moving through them. Then it removes the floor from the request list and checks if there is another request.

If so the elevator starts moving again. If not it enters the state stand. Down: like up but in reverse direction.There are additional signals:. alarm. The elevator stops. And if it is on a floor, the doors open, the request list is cleared, the requests moved back to the bank. door open.

Design Software Free Download

Opens the doors if an elevator is on a floor and not moving. door closes. Closed the door if they are open.EDIT:Some elevators don't start at bottom/firstfloor esp. In case of skyscrapers.minfloor & maxfloor are two additional attributes for Elevator. I've seen many variants of this problem. One of the main differences (that determines the difficulty) is whether there is some centralized attempt to have a 'smart and efficient system' that would have load balancing (e.g., send more idle elevators to lobby in morning). If that is the case, the design will include a whole subsystem with really fun design.A full design is obviously too much to present here and there are many altenatives.

The breadth is also not clear. In an interview, they'll try to figure out how you would think. However, these are some of the things you would need:.Representation of the central controller (assuming there is one).Representations of elevators.Representations of the interface units of the elevator (these may be different fromelevator to elevator). Obviously also call buttons on every floor, etc.Representations of the arrows or indicators on each floor (almost a 'view' of the elevator model).Representation of a human and cargo (may be important for factoring in maximal loads).Representation of the building (in some cases, as certain floors may be blocked at times, etc.). Thing's to be Consider While the Elevator System, ElevatorFloor/Location IdentifierNumber of stepsRotation speedDaterangeInstallationDateMaintainenceDateDepartment IdentifierAllowedWeightDetail / DescriptionPoison Ratio (Statistics)StartStopSetDirectionSetRotationSpeedEmergencyStop = Stop + AlertEmergencyAccidentSenser HandlerEach button press results in an elevator request which has to be served.

Each of these requests is tracked at a global placeThe number of elevators in the building will be determined by the user. The building will contain a fixed number of floors.

The number of passengers that can fit into the elevator will be fixed. The passengers will be counted as they leave the elevator at their destination floor. The destination floor will be determined using a 'random' Poisson interval. When all of the passengers in the elevator have reached their destination floors, the elevator will return to the lobby to pickup more passengers. Main thing to worry about is how would you notify the elevator that it needs to move up or down. And also if you are going to have a centralized class to control this behavior and how could you distribute the control.It seems like it can be very simple or very complicated.

If we don't take concurrency or the time for an elevator to get to one place, then it seems like it will be simple since we just need to check the states of elevator, like is it moving up or down, or standing still. But if we make Elevator implement Runnable, and constantly check and synchronize a queue (linkedList). A Controller class will assign which floor to go in the queue. When the queue is empty, the run method will wait (queue.wait ), when a floor is assigned to this elevator, it will call queue.notify to wake up the run method, and run method will call goToFloor(queue.pop).

This will make the problem too complicated. I tried to write it on paper, but dont think it works. It seems like we don't really need to take concurrency or timing issue into account here, but we do need to somehow use a queue to distribute the control.Any suggestion?

The elevator was the key to the modern city; it revolutionized the entire nature of buildings – and how people interact with them. In an industry built on innovation and problem-solving, SnapCab continues to develop creative solutions for 21st century needs and challenges.With over 15,000 installations across the continent, strong relationships with all major elevator maintenance companies, and strategic partnerships with heavyweights like Corning Incorporated, SnapCab has become the undisputed leader in elevator interior systems.

But we’re not letting that slow us down; continuous innovation and improvement continues to be the foundation of our high-rising company. What Is The SnapCab System?The SnapCab elevator interior system consists of modular, interlocking panels that stack one on top of the other. Thanks to this streamlined pioneered by SnapCab Founder and CEO Glenn Bostock, the job can be done in a fraction of the time and at a fraction of the cost. Instead of days, elevators can be remodeled in hours. One-day installation delivers significant cost savings to customers and ensures minimal downtime for their elevators.Our system makes remodeling elevators interiors a far more efficient process in two main ways:. Before Installation: SnapCab’s relieve the headache of code compliance and weight restrictions when planning.

All are E84 tested in their end use-configurations, so that the interiors meet the ASME code requirements. And every quote comes with the product weights listed so there’s no guesswork. During Installation: Not only are the interlocking panels simple and quick to install, the process is also streamlined because we include every single item elevator mechanics need to complete the job – right down to the garbage bags to dispose of the waste. This entirely eliminates the downtime for trips to the hardware store or back to the shop. At the same time, we do not sacrifice aesthetics for ease and convenience. Customers can choose from an enormous variety of quality materials, finishes, and styles so that they meet their unique design goals and create the look and feel they want.Why Elevator Interiors?

SnapCab: A History of Craftsmanship and Problem SolvingThe seeds for SnapCab were sown in Glenn Bostock’s parents’ basement, where, as a child, he spent hours working with wood. After studying Fine Wood Working at Bucks County Community College and apprenticing as an ecclesiastical furniture maker, Glenn opened his own shop specializing in high-end furniture and custom cabinetry, as well as wood repair and refinishing.One day, a company contacted Glenn about remodeling its elevators to match the reception desk. As word got out, he spent more and more time remodeling elevator interiors, a job few people did – and one that was slowed and complicated by the arduous practice of removing the entire cab to work on it, or using complicated clip systems that took 3 to 4 days to install.To remedy this, Glenn developed his patented panel system: SnapCab was born, and we have been helping customers save time, money, and aggravation on remodels and new builds for 20 years.A craftsman at heart, Glenn and the SnapCab team devote exacting, meticulous care into all of our work. The result is visually stunning interiors that meet applicable codes – and customers’ high expectations. Less Hassle, Better Results: The Simple SnapCab PhilosophySnapCab’s philosophy can be summed up easily: Elevator interiors simplified. Everything – from designing to ordering to installing – is designed for ease, convenience, and superior results. The models in our catalog can be modified to fit specific aesthetic requirements, so clients always have the ability and flexibility to achieve their.

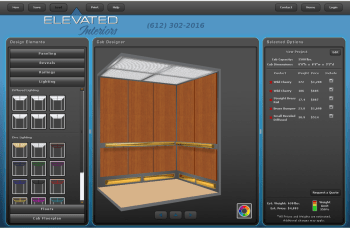

Altering their design to fit within standard models cuts down on the cost and time of fully custom jobs – without cutting down on aesthetics and quality.Additionally, with free design services, including presentation boards and 3D renderings, customers can see their design coming to life before their interior ever arrives in the building.All of our catalogue models are E84 end-use configuration tested. That is, the individual components are assembled as a unit (as they will be in the customer’s elevator interior) and then tested to ensure safety and code-compliance. Lean and Mean: How Smarter Manufacturing Enables Better Customer ServiceSnapCab values continuous improvement. The Lean Manufacturing model encourages our entire team to innovate ways to improve quality, reduce lead-time, decrease waste, and focus on teamwork and effective communications. What does this mean for our customers? High-quality products delivered on time, at the lowest possible cost and with greater efficiency.We employ methods such as 5S (Sort, Shine, Set in order, Standardize, and Sustain), Total Productive Maintenance, Kanbans, Value Stream Mapping, and more, to efficiently and quickly provide high-quality products for exceptional elevator interiors – and pass the cost and resource savings on to our customers.Our Lean manufacturing process was one of the factors that caught the eye of Corning Incorporated (creators of Gorilla® Glass). Together, we can leverage our respective histories of innovation to develop creative solutions for the next generation of elevator interiors.

Remodels and New Builds: Simplify Your Elevator InteriorsSnapCab systems work with all elevator cab shells; our versatile solutions can and will enhance the appearance and durability of our customers’ interiors. In addition to world-class interior panels and ceilings, we provide thoughtful, timely, and high-quality service and support to simplify remodels – or new builds – every step of the way.Ask the expert!

Contact Caleb Morrison. Post navigation.